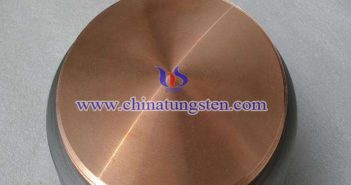

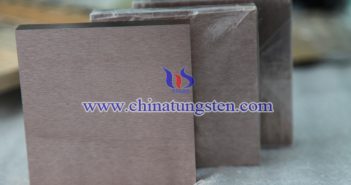

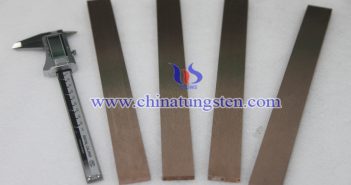

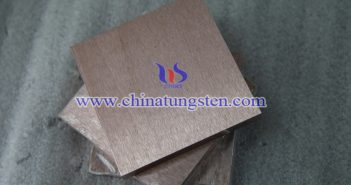

Tungsten copper block is used in the most economical way for electrode electrical discharge machining (EDM) and electrochemical machining (ECM). The spark erosion characteristics and good electron emission characteristics of these sintered products make them excellent EDM electrode materials. They have excellent wear resistance, good material removal rates and the ability to maintain good detail. More details of tungsten copper block please visit ?http://www.tungsten-copper.com/tungsten-copper-plate.html Tungsten copper block is used in ECM electrodes because they conduct high currents and resist deformation…