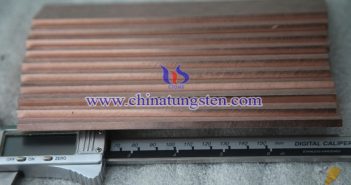

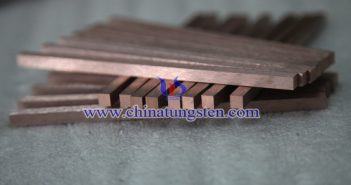

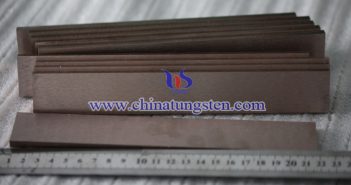

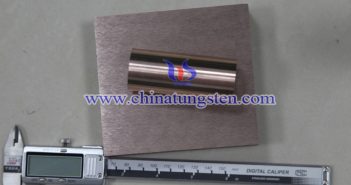

W80 tungsten copper bar is composed of 80% W and 20% Cu so that high hardness and melting point characteristics of tungsten is more obvious. Its density is up to 15.15g/cm3, hardness reaches more than HB140, but due to less Cu, conductivity is decreasing to 34%IACS, softening temperature is ≥900℃,the bending strength is 980, the thermal conductivity is 190-210(wm/k) and the coefficient of expansion is 8.0-8.5(10-6K). More details of W80 tungsten copper bar please visit ?http://www.tungsten-copper.com/tungsten-copper-bar.html W80 tungsten copper bar…