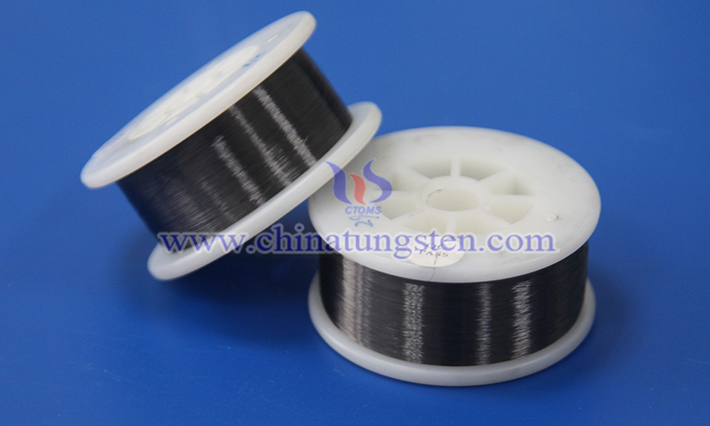

As a common material, tungsten wire is widely used to make filaments and other high-temperature components, especially in light bulbs and electronic devices. The following are the advantages and disadvantages of tungsten wire:

1. Advantages of Tungsten Wire:

High melting point: Tungsten has an extremely high melting point (about 3422°C), the highest among known metals, and is suitable for use in high-temperature environments, such as incandescent lamp filaments.

High strength and hardness: Tungsten wire has excellent mechanical strength and wear resistance, and can withstand large mechanical stress and high temperature environments.

Good conductivity: Tungsten wire has good electrical conductivity and is suitable for scenes where current needs to pass, such as filaments or electrodes.

Corrosion resistance: Tungsten has strong corrosion resistance to most chemicals, especially at high temperatures.

Thermal stability: Tungsten wire is not easy to deform or volatilize at high temperatures, and is suitable for long-term work in high-temperature environments.

2. Disadvantages of Tungsten Wire:

Brittleness: Tungsten wire is brittle at room temperature and easy to break. Care should be taken during processing and installation to avoid mechanical shock.

High cost: Tungsten is a rare metal with high extraction and processing costs, which makes tungsten wire expensive.

High density: Tungsten has a high density (19.25 g/cm3), which makes tungsten wire heavy and unsuitable for applications that require lightweight design.

Oxidation problem: Tungsten wire is easily oxidized when exposed to air at high temperature and needs to be used in a vacuum or inert gas environment, which increases the complexity of equipment design.

High energy consumption: When tungsten wire is used in incandescent lamps, the energy conversion efficiency is low and most of the energy is lost in the form of heat, which is more energy-consuming than modern LED lamps and other technologies.