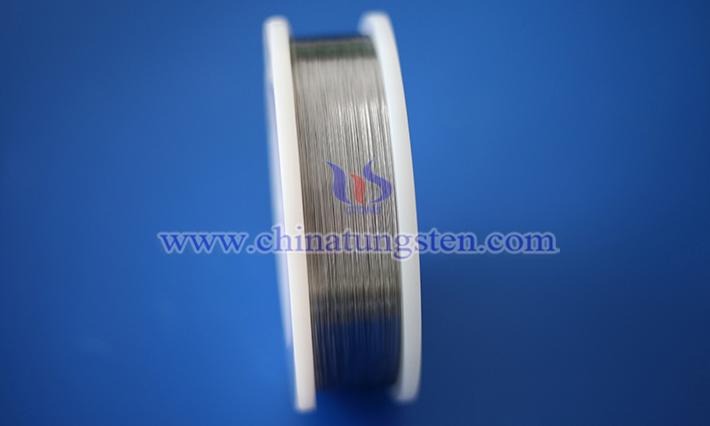

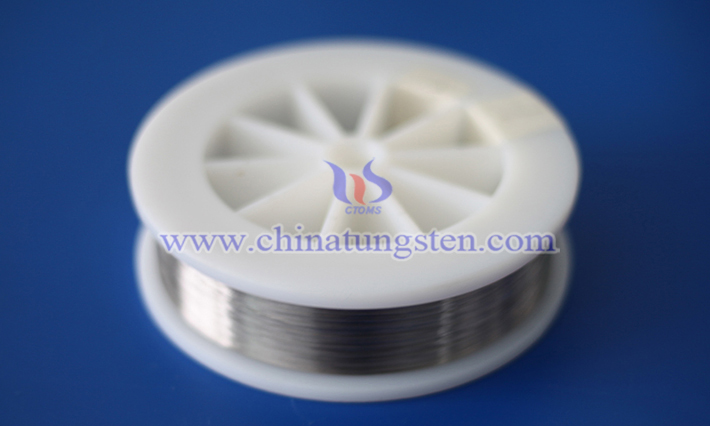

Cleaned Tungsten Wire refers to a filament made of tungsten metal. It is widely used in various industrial and scientific fields because of its high melting point (about 3422°C), high strength and good conductivity. The surface of cleaned tungsten wire is generally treated with alkali washing, showing a silver-gray metallic luster, so it is called "white tungsten wire".

1. The main characteristics of cleaned tungsten wire

High melting point: Tungsten is one of the materials with the highest melting point among known metals and is suitable for use in high temperature environments.

High strength: Tungsten wire has excellent mechanical strength, tensile resistance and wear resistance.

Good electrical and thermal conductivity: makes it suitable for electric light sources and other electronic devices.

Corrosion resistance: Tungsten has good corrosion resistance to most chemicals.

2. The main use of cleaned tungsten wire

Lighting industry: Cleaned tungsten wire is the core component of traditional incandescent lamps and halogen lamps, used as filaments because it can emit light at high temperatures.

Electronic equipment: used as emitters or heating elements in vacuum tubes, cathode ray tubes (CRTs), and other electronic devices.

High temperature industry: such as heating elements in high temperature furnaces, because they can withstand extreme temperatures.

Medical and scientific research: used as electron emission sources in equipment such as X-ray tubes and mass spectrometers.

3. Production process of tungsten filament

Tungsten filament is usually made by powder metallurgy process, including:

(1) extracting pure tungsten powder;

(2) pressing into rods or billets;

(3) forming tungsten rods by high temperature sintering;

(4) drawing the tungsten rods into filaments by wire drawing process;

(5) obtaining tungsten filaments after electrolytic cleaning and polishing.