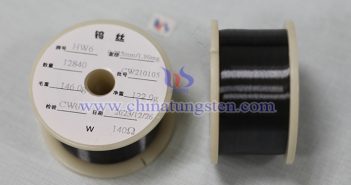

The use of tungsten wire in glass heating is mainly as a heating element, using its high melting point, high temperature resistance and oxidation resistance to provide a high temperature and stable heat source to meet the needs of glass processing and treatment. The following are the specific applications of tungsten wire in glass heating: 1. Glass Melting Tungsten wire heating can provide enough high temperature to melt the glass raw materials into liquid. This is the basic step in…