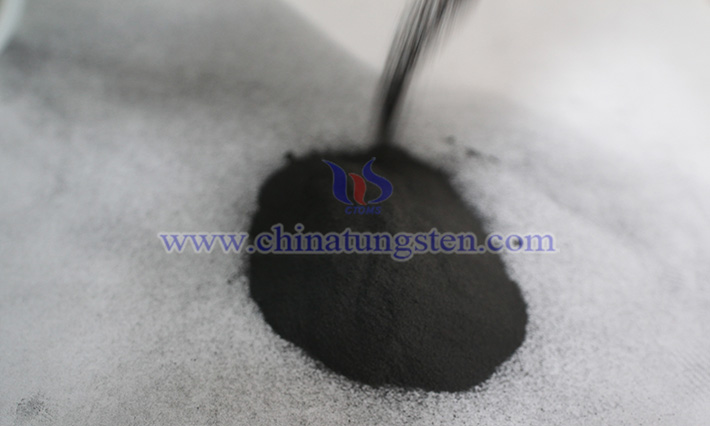

Tungsten carbide powder (WC powder) is a compound composed of the refractory metal tungsten and non-metallic carbon, featuring high density, high melting point, high strength, high hardness, heat resistance, corrosion resistance, wear resistance, and good electrical and thermal conductivity. These properties make it an ideal material for hard alloy tools.

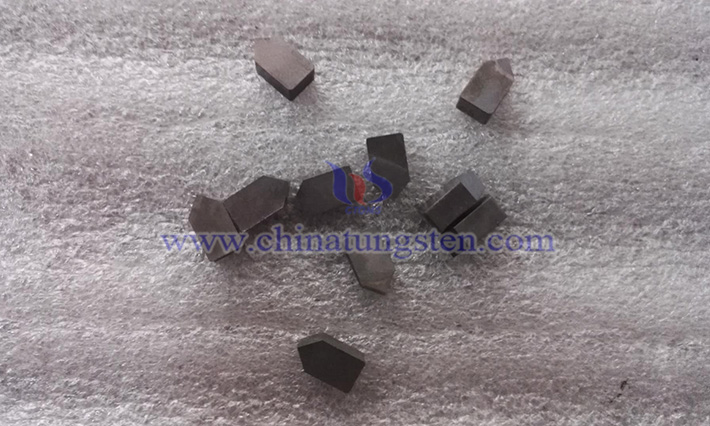

However, due to the high brittleness and poor toughness of pure WC powder, it is common to add appropriate amounts of binders such as cobalt (Co), nickel (Ni), chromium (Cr), molybdenum (Mo), titanium (Ti), and copper (Cu) when producing hard alloy tools with superior overall performance.

Specifically, hard alloys with WC powder as the hard phase and Co as the binder phase are more suitable for cutting tools. Their good thermal conductivity helps dissipate cutting heat from the tool tip, reducing the tip temperature and preventing overheating and softening. Additionally, their high bending strength and impact toughness effectively lower the probability of chipping during cutting, while their excellent machinability (far surpassing high-speed steel) allows for the grinding of sharp edges.

Hard alloys with WC powder as the hard phase and Ni as the binder phase are more suitable for corrosion-resistant components. They offer stronger corrosion resistance compared to tungsten-cobalt hard alloy tools, making them ideal for environments with various corrosive media. Moreover, WC-Ni hard alloy seals are suitable for use in low-temperature, high-temperature, vacuum, and high-pressure conditions.

Hard alloys composed of WC, TiC, and Co exhibit high hardness, good heat resistance, high compressive strength, good oxidation resistance, and poor thermal conductivity, making them suitable for machining steel.

It should be noted that the specific physical properties of hard alloys vary with different raw material ratios. If one or more layers of refractory hard compounds, such as carbides or nitrides, are coated on the surface of the hard alloy, the alloy’s high wear resistance and high toughness can be further harmonized, making it more suitable for high-speed cutting.