Tungsten wire heating glass is suitable for processes that require high temperature and precise temperature control. The advantages are high efficiency and durability, but the problems of oxidation, cost and equipment complexity need to be solved. In practical applications, it is necessary to weigh the use according to the specific process requirements. The advantages and disadvantages of using tungsten wire to heat glass are as follows:

1. Advantages:

High Temperature Performance: Tungsten wire has an extremely high melting point (about 3422°C), which is suitable for heating glass at high temperatures and can achieve fast and uniform heating.

Efficient Energy Conversion: Tungsten wire can efficiently convert electrical energy into thermal energy when powered on, with high heating efficiency, which is suitable for glass processing scenarios that require precise temperature control.

Durability: Tungsten wire has good chemical stability in high temperature environment, is resistant to oxidation (under vacuum or inert gas protection), and has a long service life.

Precise Control: By adjusting the current, the heating temperature of the tungsten wire can be accurately controlled, which is suitable for glass forming, annealing and other processes.

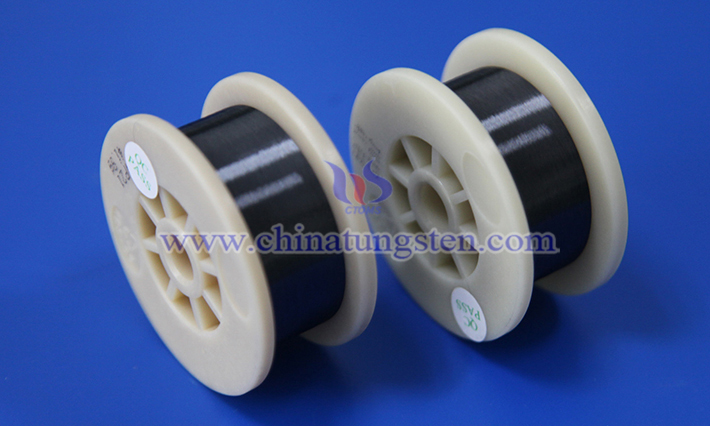

Wide Applicability: It can be used in a variety of glass processing scenarios, such as glass melting, wire drawing, etc.

2. Disadvantages:

Oxidation Problem: Tungsten wire is easily oxidized at high temperatures in the air, and needs to be used in a vacuum or inert gas (such as argon, nitrogen) environment, which increases the complexity and cost of the equipment.

High Cost: Tungsten is a rare metal with a high price, and the cost of processing it into filaments is not low, and the maintenance cost is also high.

High Energy Consumption: Although the heating efficiency is high, tungsten wire heating usually requires a large amount of electrical energy input, and the operating cost may be high.

Equipment Complexity: To prevent oxidation, a vacuum or inert gas protection device is required, which increases the complexity of equipment design and operation.

Glass Contamination Risk: If the tungsten wire releases particles due to overheating or breakage, it may contaminate the glass surface and affect product quality.