Molybdenum sheet, with its excellent high-temperature resistance, thermal properties, chemical stability, and processability, is the preferred material for covers in sapphire crystal growth furnaces.

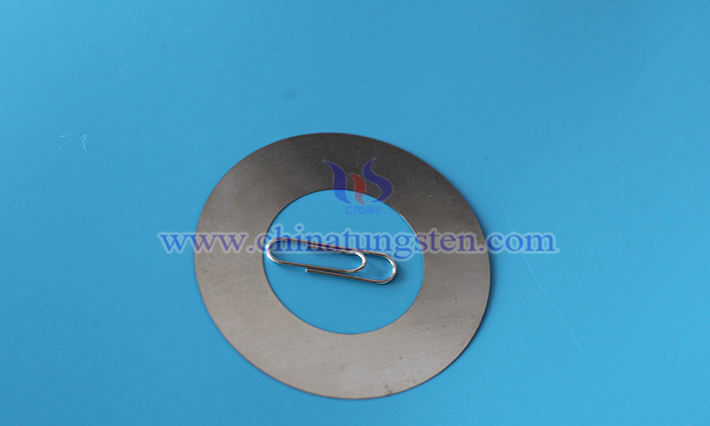

CTIA GROUP LTD molybdenum sheet

The sapphire crystal growth process occurs at extremely high temperatures, often exceeding 2,000°C in common methods like the Kyropoulos or Czochralski processes, where ordinary materials would fail. Molybdenum sheet, with its high melting point, maintains a stable solid structure under such conditions, resisting melting or softening, ensuring the cover's integrity and functionality during prolonged high-temperature operations.

Molybdenum sheet has high infrared reflectivity, a critical feature for sapphire crystal growth furnaces. During crystal growth, heat sources like graphite heaters emit significant radiant heat. Molybdenum sheet covers effectively reflect this heat, concentrating it in the crystal growth zone and minimizing heat loss to the furnace exterior, thus improving energy efficiency. Through heat reflection and redistribution, molybdenum sheet covers optimize the furnace's temperature field distribution, ensuring a more uniform and stable temperature at the crystal growth interface.

CTIA GROUP LTD molybdenum sheet

Molybdenum sheet has a low thermal expansion coefficient, effectively reducing stress from thermal expansion and contraction. In sapphire crystal growth, the furnace undergoes frequent temperature adjustments, with drastic changes from heating to cooling phases. Molybdenum sheet covers, with their low thermal expansion, resist deformation or cracking, ensuring uninterrupted crystal growth.

Sapphire crystal growth typically occurs in inert or reducing atmospheres, such as argon or nitrogen, to prevent oxidation of the Al?O? melt. Under these conditions, molybdenum sheet exhibits excellent chemical stability, neither reacting with the protective gases nor with the molten sapphire raw material, thus preventing contamination of the growth environment. In contrast, if a metal prone to oxidation or reaction with sapphire raw materials were used as the cover, it might form an oxide layer at high temperatures, which could flake off and contaminate the melt, introducing impurities that significantly reduce the sapphire's purity and quality.

Molybdenum sheet offers good processability, allowing it to be shaped into various complex forms through rolling, cutting, and welding to meet the design needs of different sapphire crystal growth furnaces, whether circular, square, or custom-shaped covers.