Molybdenum-copper alloy (Mo-Cu) is a material composed of molybdenum with high melting point and high strength and high thermal conductivity and high electrical conductivity, which is commonly used in thermal management and structural packaging in high-end fields such as electronic devices, power modules, and aerospace. Due to its unique thermal and mechanical properties, the alloy occupies an important position in metal encapsulation materials.

From the perspective of thermal conductivity and thermal expansion coefficient, Mo-Cu has a high thermal conductivity (generally between 180220 W/m·K), second only to pure copper and copper-based materials, and its thermal expansion coefficient (CTE) is about 68×10??/K, which can be optimized by adjusting the ratio of molybdenum to copper to match silicon (Si), The thermal expansion properties of common semiconductor materials such as gallium arsenide (GaAs) significantly reduce thermal stress. This advantage makes it outstanding in electronic packaging with high reliability requirements.

In contrast, the traditional copper-tungsten alloy (W-Cu) also has good thermal conductivity and tunable thermal expansion properties, but due to the higher density of tungsten (19.3 g/cm3) and the processing performance is not as good as molybdenum, the W-Cu material is slightly inferior in terms of weight and machinability. On the other hand, although AlSiC (metal matrix composites) have low density and excellent thermal expansion properties, their thermal conductivity is generally low (about 170 W/m·K), which is not suitable for scenarios with extremely high heat flux density.

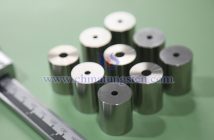

In terms of processability, the advantages of Mo-Cu are even more obvious. Molybdenum has better ductility than tungsten, and copper has excellent machinability, so Mo-Cu alloy has better adaptability in secondary processing such as machining, welding, wire cutting, etc., and is suitable for high-precision, complex structure parts manufacturing.

In addition, from the perspective of material stability and environmental adaptability, molybdenum-copper alloy has good high-temperature stability and oxidation resistance, and is suitable for high-temperature environment under vacuum or inert atmosphere, while aluminum matrix composites and high-conductivity copper alloys are prone to performance deterioration under high temperature or oxidation conditions.